THE MATERIALS

QUALITY AND VERSATILITY

Alpro proudly offers a range of high-quality materials, including brass, corten steel, stainless steel, and galvanized steel, each with their own unique properties and finishes. Brass offers both luxury and tradition in its glossy or burnished finishes, with its natural oxidization providing self-protection ideal for use in difficult environmental conditions. Corten steel’s resistance to corrosion and self-protection with a patina on the surface allows for the realization of high-performing fixtures of large dimensions, while its gradual change in colors evokes the passing of time. Stainless steel’s resistance to corrosion and low thermal conductivity allow for sections of reduced dimensions, lessening the visual impact of fixtures while enhancing luminosity. Galvanized steel’s thin, strong, and high-performing profiles provide maximum versatility in design and reduce visual impact, ideal for customized architecture projects.

Our natural and precious materials offer the advantage of creating tailor-made solutions for contemporary architecture or renovation projects.

Select Metals

The 4 select metals which we offer to our clients are galvanised steel, stainless steel, corten steel and brass.

Your design project can benefit immensely from the qualities of these select materials. The different surfaces and finishes of our materials enhance the architect’s creativity and allow wider freedom of expression.

With the help of our select materials, architects can interpret in their projects the latest trends of contemporary architecture, or a traditional architectural style.

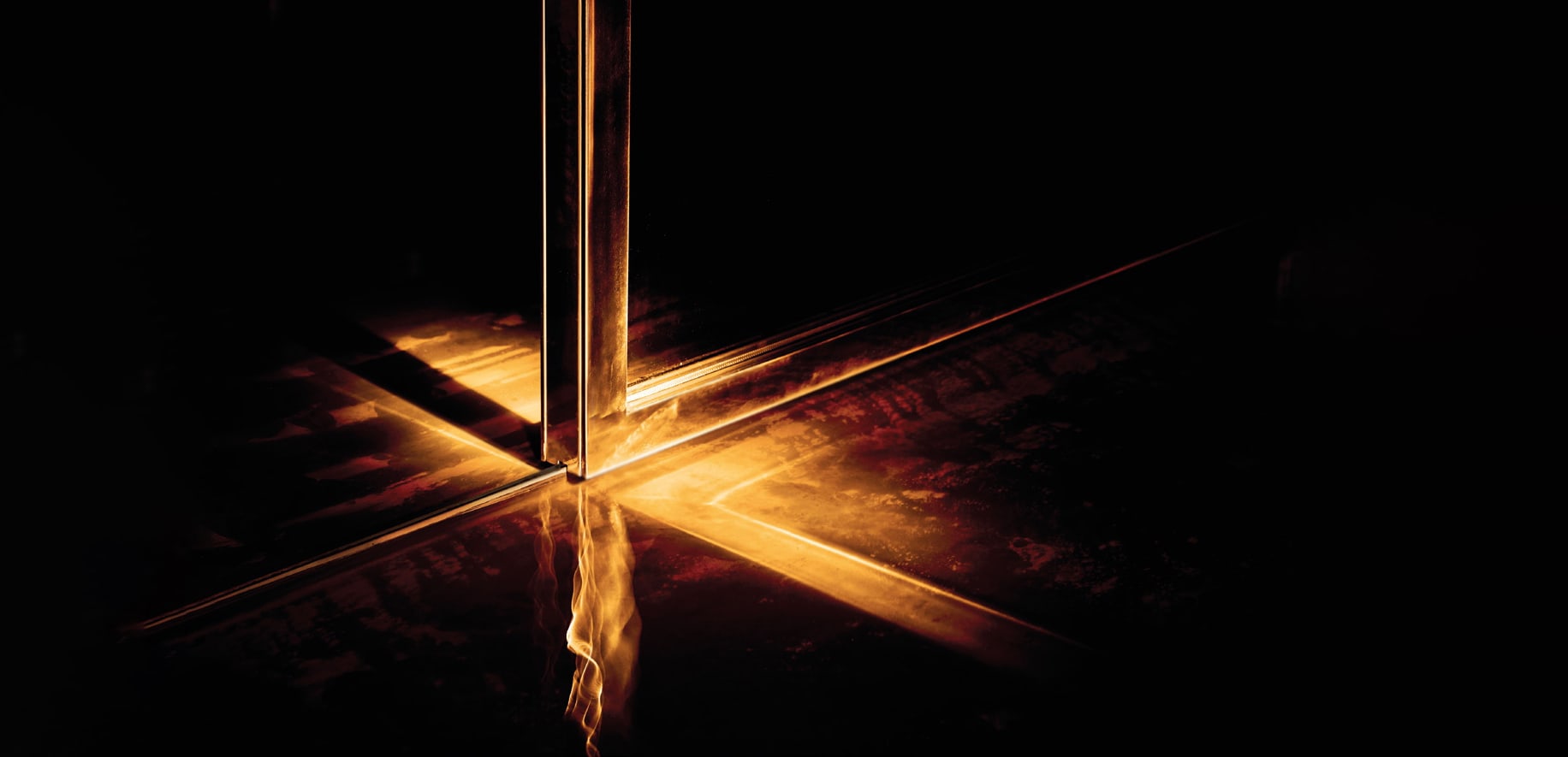

BRASS

The unique blend of color, luster, and durability in this alloy makes it a coveted and distinctive element for architectural applications, suitable for both contemporary and historic designs. Glossy or burnished brass surfaces can exude a sense of opulence and sophistication or pay homage to traditional aesthetics. As the alloy is exposed to the elements, it takes on the richness and reflections of antique bronze while maintaining its structural integrity. The natural oxidization process provides a layer of protection that makes the final product ideal for use in challenging environments, such as marine settings. Secco Sistemi utilizes the OT67 alloy, which boasts a high copper content (67%) for superior resistance to corrosion and 33% zinc content to enhance mechanical properties, such as hardness and load capacity. This alloy is also eco-friendly, with a 100% reusability rate, making it an excellent choice for sustainable design.

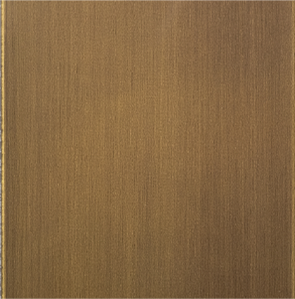

1 Just Natural Brass

1 Just Natural Brass

2 Burnished Brass

2 Burnished Brass

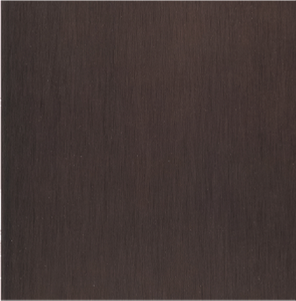

3 Burnished Brass

3 Burnished Brass

4 Burnished Brass

4 Burnished Brass

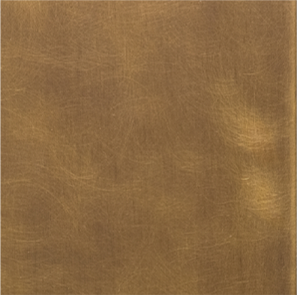

5 Burnished Brass

5 Burnished Brass

6 SB Burnished Brass

6 SB Burnished Brass

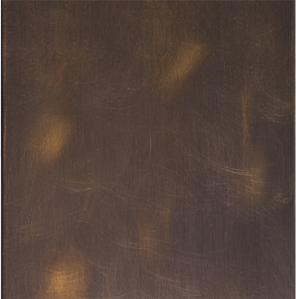

7 SB Burnished Brass

7 SB Burnished Brass

8 SB+HM Burnished Brass

8 SB+HM Burnished Brass

9 SB+HM Burnished Brass

9 SB+HM Burnished Brass

Corten Steel

Corten steel possesses remarkable resistance to corrosion, up to 6-8 times greater than that of conventional steels, and exhibits double the tensile strength. This unique blend of properties enables the creation of large, high-performance fixtures with thin sections. Corten steel also has the remarkable ability to self-protect with a patina that forms on the surface, halting the spread of corrosion and imbuing the material with hues and tones that evoke the passage of time. With its expertise in technological innovation and keen sense for contemporary architectural trends, Secco Sistemi was the first to pioneer the use of corten steel in the production of frames and fixtures.

Oxidized

Oxidized

Oxidized waxed

Oxidized waxed

Stainless Steel

Stainless steel, an alloy of iron, carbon, nickel, and molybdenum, offers exceptional durability and resistance to corrosion when exposed to atmospheric agents. This material requires minimal maintenance and can be recycled up to 90%. Due to its unique physical and mechanical properties, stainless steel sections can be made in smaller dimensions, reducing the visual impact of fixtures while increasing the luminosity of interiors. Thermal break elements made from stainless steel also have a low transmittance value, as their thermal conductivity is 10 times lower than that of aluminum. Secco Sistemi employs two types of stainless steel to manufacture its sections: the more common satin-finished 304 and the 316L, which is ideal for maritime environments and available in a scotch-brite or glossy finish.

Satin finish

Satin finish

Gloss

Gloss

Scotch-brite

Scotch-brite

Burnished

Burnished

Galvanized Steel

Steel’s physical and technical properties allow for the creation of thin, robust, and high-performing profiles, resulting in maximum design flexibility and reduced visual impact. This creates a sense of lightness and transparency, providing increased luminosity in interior spaces. Secco Sistemi uses the FeP02 alloy, with a hot zinc coating of GZ200 (200 g/m3 on both sides), providing internal and external protection against oxidation. Skinpassing the zinc layer results in a smooth finish that ensures better adhesion during the painting process, which utilizes polyester powder coating that is furnace-baked at 180°C, resulting in an ideal finish.

VARNISHED

VARNISHED

THE QUALITIES OF STEEL

Your design project can benefit immensely from the qualities of these select materials. The different surfaces and finishes of our materials enhance the architect’s creativity and allow wider freedom of expression.

Let’s discover together the main qualities of steel.

- Natural

- Solid

- Precious

- Ductile

- Versatile

- Long-lasting

- Structural resistence

- Recyclable and re-usable

- Necessitating little maintenance

Unique projects call for unique solutions

Either for drawing your custom design project or for placing the perfect accent piece inside an interior, you require high-quality profiles for doors and windows, skylights, or accessories.

WRITE TO US

Your project can benefit from custom made doors&windows which meet residential and commercial needs. Contact us now, and together we can find solutions for your project.

OR SEND US A DIRECT E-MAIL